MEP contractors are a crucial part of the building design team, responsible for Mechanical, Electrical, and Plumbing design in a structure. The AEC market is a competitive zone and to stay at the forefront the MEP contractors should emphasize timely completions and working within budget.

The other related trades including the architect, surveyors, and fabricators should have synchronized roles and deliverables with the MEP consultants at the pre-construction stage. MEP BIM Modeling Services play a crucial role in increasing collaboration, eliminating design clashes, and executing a hassle-free onsite installation.

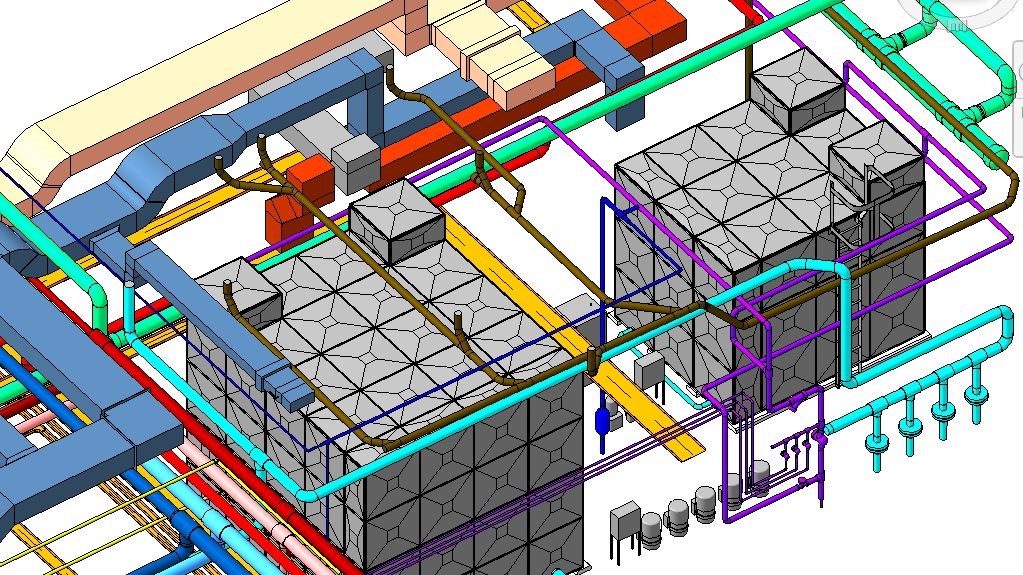

The BIM setup provides MEP project teams insights into design and constructability with elaborative structural visualization.

The construction process is accelerated with better project control, proactive conflict resolution, improved collaboration, the presence of reality simulation, and reduced material waste.

A large percentage of time and costs is saved by reinforcing BIM Modeling Services into construction workflows.

The absence of MEP drawings and detailing leads to a constant struggle for the MEP contractors to resolve spatial issues.

These problems further result in rework, construction errors, and material wastage, ultimately leading to budget and time overruns.

The most significant purpose of MEP drawings is to ensure the structural stability of the building and resolve clashes at the pre-construction stage.

These drawings provide a clear roadmap on how to complete the process seamlessly and timely, abiding by the project budget.

Challenges of using conventional methods for MEP drawings

The Conventional method of creating MEP drawings is using Autocad, which comes with its own set of challenges that include:

- The interdisciplinary errors and coordination issues result in constant re-designing and re-working.

- The rework leads to cost and time overruns, resulting in project delays.

- The lack of visualization and coordination facilities between these services leads to unidentified clashes in drawings.

- The traditional CAD process does not provide high-quality design quality.

Types of MEP Drawings

MEP drawings are classified into five different categories:

- Penetration drawing

MEP systems involve components penetrating floor and wall spaces in the building. Penetration drawings help the contractors and onsite personnel ensure the precision of penetration based on accurate dimensions.

These drawings also analyze the structural integrity of buildings and assess the structure for potential issues in the future.

- Shop drawing

Shop drawings are a set of drawings developed to interpret the actual design intent, field conditions, and project-related data.

These drawings are developed as per the industry standards and with utmost dimensional accuracy. These MEP drawings account for manufacturing dimensions, finer details, and specific instructions.

- Spool drawing

Spool drawings provide accurate details for manufacturing customized and dimensionally precise spools. These spools are used for smooth plumbing installation during construction on site.

- Coordination drawing

Coordination drawings are used to identify and resolve MEP collisions. The identification of these clashes minimizes errors, reduces manufacturing costs, and mitigates time overruns.

- As-built drawing

As-built drawings facilitate the update of MEP systems for already existing structures. These drawings promote a smooth renovation and allow the team to conduct precise documentation of the project.

These drawings reflect the changes that have been made in the initial ME layout over the years and enable the MEP contractors to design better.

Why should the MEP BIM Modeling services be adopted for the AEC projects?

The integration of BIM MEP systems is a complicated process due to design, spatial, and interrelation problems involved in the MEP systems. Here are some of the reasons that support the adoption of BIM Modeling services by MEP contractors:

- 3D Visualization

The most common benefit of using 3D BIM modeling for MEP drawings is the ease of visualizing the pipelines and ductwork. It eliminates the possibility of clashes and interdisciplinary issues, saving time and effort for the MEP contractors.

The detailed visualization provides clarity about how to add equipment, and their preferable clearances, and allows for changes before execution on site.

- Procurement and Logistical Planning

The MEP systems involve various small and large elements such as wires and pipes that occupy space, planning bandwidth, and financial resources.

To avoid chaotic situations, the MEP contractors can use BIM that streamline the material procurement and logistical planning process.

The clarity about the requirements eliminates the chances of material wastage and allows the contractors to deliver only necessary material on site. The accurate material estimates save money and remove the hassle of bulk storing in advance.

- Complete control over the project

The BIM Modeling services allow the contractors to get an overall view of various components from the walls with the electrical wires, the plumbing layout, and the ceiling elevations.

All the data is available on a common platform accessible by all MEP contractors involved in the construction project.

The detailed information provides complete control over the project’s scope of work and reduces unnecessary wastage of resources.

- Solve Challenges

Sometimes the bigger challenges for MEP contractors are the smaller design components in a project. It is easier to model and place the large components to their exact measurements compared to the smaller ones.

BIM Modeling helps contractors solve this challenge by easily modeling, designing, and creating smaller components with utmost detail.

- Eliminate unnecessary Interferences

Clashes like overlapping of electrical and plumbing trays or any event of the same nature are common in construction projects. These are likely to occur in projects involving multiple team members in different facets of the project.

MEP BIM Modeling Services can be used to detect such clashes during the design phase and analyze the potential solution. This can save the time spent on a project and reduce the project costs.

Conclusion

MEP BIM Modeling Services are rapidly adopted in the industry based on productivity, coordination, and performance analysis.

For many firms, a significant transition is observed from traditional 2D CAD to 3D modeling to achieve an accurate design.

BIM helps in identifying efficient workflows, building precise structures, and detailed MEP drawings, as per client requirements. BIM adoption can help to generate more productive and effective MEP drawings for onsite execution.