Bimetal sheets, a remarkable product of advanced engineering, have revolutionized various industries due to their unique properties and versatile applications. These sheets are compose of two distinct metals bonded together, each with its characteristics. Combining these metals amplifies their benefits and opens up many modern engineering and construction possibilities. In this blog, we’ll delve into the applications of bimetal sheet, exploring how they are making a significant impact in shaping the present and future of these industries.

Understanding Bimetal Sheets: Composition and Structure

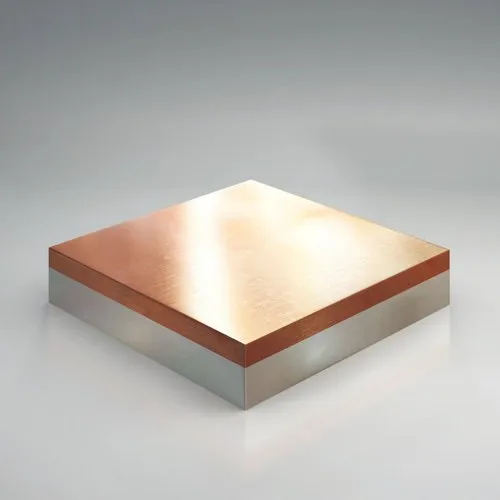

Before delving into their applications, let’s understand the fundamentals of bimetal sheets. As the name suggests, these sheets comprise two different metals or alloys, typically with varying thermal expansion coefficients. Common combinations include steel and aluminum, steel and copper, or copper and aluminum. The metals are precisely bond together through a high-pressure process, resulting in a durable composite material with distinct properties.

Key Properties that Drive Applications

The bimetal sheets’ properties are derive from the combination of metals, allowing for a broader range of applications:

Thermal Expansion Differential: The dissimilar thermal expansion coefficients of the metals result in a controlled bending or curving effect when subjected to temperature changes. This property is harnesse in applications where precise temperature control or sensing is needed.

High Strength and Durability: Bimetal sheet inherit the strength and durability of the constituent metals, making them robust and capable of withstanding heavy loads and harsh environments.

Electrical Conductivity: Depending on the metals used, bimetal sheet may exhibit enhanced electrical conductivity, making them suitable for various electrical applications.

Corrosion Resistance: Some combinations of metals offer excellent corrosion resistance, ensuring longevity and reliability in diverse environments.

Applications in Modern Engineering and Construction

1. Thermostats and Temperature Control Systems

Bimetal sheets are extensively use in thermostats for heating, ventilation, and air conditioning (HVAC) systems. The differential thermal expansion of the metals allows for precise temperature control, enabling thermostats to activate or deactivate based on temperature changes. This application is critical for maintaining comfortable indoor environments and energy efficiency.

2. Electrical Contacts and Switches

Bimetal sheets find applications in electrical devices, such as switches and circuit breakers, where their unique properties help create reliable electrical contacts. The controlled bending due to temperature changes ensures stable electrical conductivity, making them indispensable in the electrical industry.

3. Industrial Sensors and Gauges

In industrial settings, bimetal sheet are employe in sensors and gauges to detect temperature changes accurately. Their predictable response to varying temperatures allows for precise measurements, monitoring, and control in industrial processes.

4. Automotive Industry

Bimetal sheet are use in the automotive industry for various applications, including engine components and temperature sensors. Their ability to withstand high temperatures and provide accurate readings makes them ideal for engine temperature monitoring and control.

5. Aerospace Engineering

Bimetal sheets play a crucial role in the aerospace industry due to their lightweight yet robust nature. They find applications in temperature-sensitive components and systems within aircraft and spacecraft, ensuring optimal performance and safety.

6. Construction Materials and Cladding

In the construction industry, bimetal sheets are utilize in cladding applications to provide structural support and aesthetic appeal. Integrating bimetal sheet enhances the durability and corrosion resistance of the construction material, making it suitable for various architectural designs.

7. Metalworking and Machining

Bimetal sheets are also utilize in metalworking and machining processes, where their properties are leveraged for specific cutting or shaping applications. The bimetal structure allows for controlled bending or deformation under the right conditions, aiding in precise metalworking operations.

8. Energy Systems and Power Generation

Bimetal sheet are integrate into energy systems and power generation equipment, aiding in efficient heat dissipation and temperature control. Their ability to respond to temperature changes makes them valuable in components like heat sinks and power generation systems.

Advancements and Future Prospects

As technology continues to evolve, so do the applications of bimetal sheet. Ongoing research and development are exploring new combinations of metals and innovative bonding techniques to create enhanced bimetal sheet with even more tailored properties. These advancements are expecte to expand the range of applications, further optimizing efficiency and performance in diverse industries.

Conclusion

Bimetal sheets have become critical in modern engineering and construction due to their unique properties and versatility. From thermostats and electrical contacts to aerospace engineering and construction materials, the applications of bimetal sheet continue to grow, showcasing their ability to address complex engineering challenges. As technology advances and new applications emerge, bimetal sheets will undoubtedly play an even more significant role in shaping the future of engineering and construction, paving the way for innovative and efficient solutions.