When it comes to industrial success, efficiency and safety are largely determined by the design of a manufacturing facility. A thoughtfully planned layout guarantees a secure working environment for staff members in addition to increasing productivity. We will explore the fundamentals of Manufacturing Plant Layout Design in this guide, with an emphasis on integrating safety and efficiency to create a peaceful and effective work environment.

Comprehending the Production Process

It is essential to have a thorough understanding of the production process before beginning the layout design. Determine the important steps, equipment, and material flow. With this information, an optimized layout that reduces bottlenecks and expedites production can be built.

Efficiency through Zoning

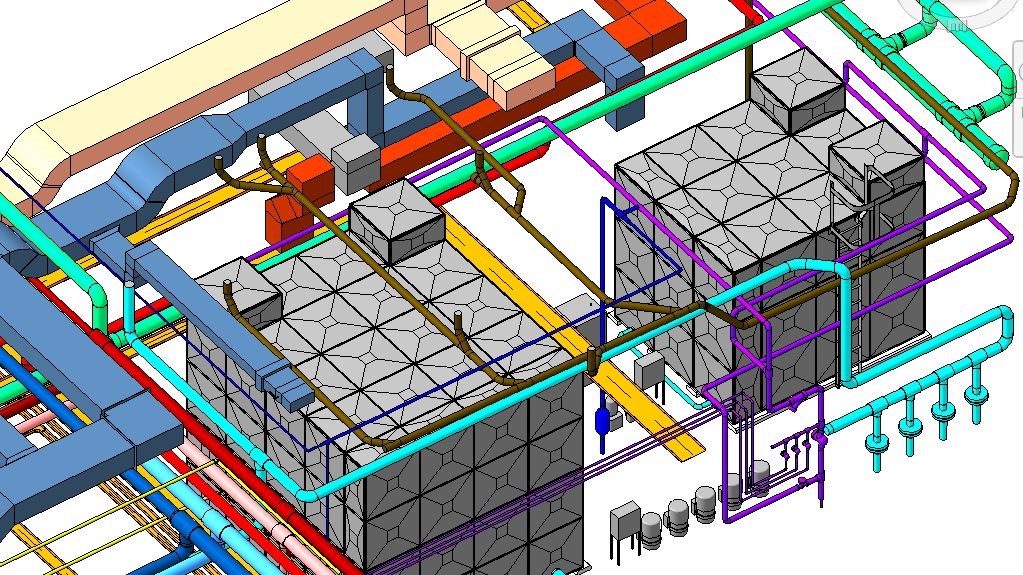

Based on the production process, divide the plant into functional zones. Set aside particular spaces for production lines, quality assurance, finished goods storage, and raw material storage. This zonation strategy makes it easier for workers and supplies to move around, which cuts down on pointless movement and boosts productivity.

Design of Flow

An effective material flow is the foundation of a well-planned layout. To reduce handling and transportation time, arrange equipment and workstations logically. In order to ensure a smooth manufacturing process, take into account the unidirectional flow of materials from raw goods to the finished product.

Adaptability and Expandability

Foresee future shifts in technology and production needs. Consider scalability and flexibility when designing the layout to facilitate simple expansion or reconfiguration. This flexible strategy guarantees that the plant can change to meet the needs of the market and industry.

Prioritizing safety

Safety in a manufacturing setting is non-negotiable. Include safety elements in the design, like clearly marked emergency exits, first aid stations, and signage. Make sure that equipment is positioned correctly to prevent mishaps, and designate specific paths to keep people away from moving machinery and pedestrians.

Comfortable Workstations

Make workstation ergonomics a top priority to improve worker health and output. Think about things like cozy chairs, adequate lighting, and convenient tool access. An ergonomic workplace helps to create a more productive and healthy workforce by lowering the risk of work-related injuries.

In summary

A plant’s layout acts as the choreographer in the complex dance of manufacturing, coordinating the movements for optimal productivity and security. To succeed in the cutthroat industrial environment, a manufacturing plant layout design that takes the production process, safety procedures, and future scalability into account is essential. By adhering to these guidelines, producers can establish a work environment that puts employee welfare first in addition to producing goods of the highest caliber.

Also Read: A Comprehensive Guide To Developing New Products With A Metal Spinning Machine Manufacturer