An efficient cooling system is critical for injection molding success. Optimized cooling channel layouts, sizes, and controls enable faster cycle times, higher production, lower defects, and reduced manufacturing costs.

Cooling optimization starts at the design stage through advanced mold flow simulations. Collaboration with experienced mold makers then refines the system for machining. Ongoing analysis and upgrades provide further improvements over a tool’s lifespan.

China mold maker increasingly leverage analysis capabilities for efficient, high-quality injection molding. Their expertise in this vital area enhances global competitiveness.

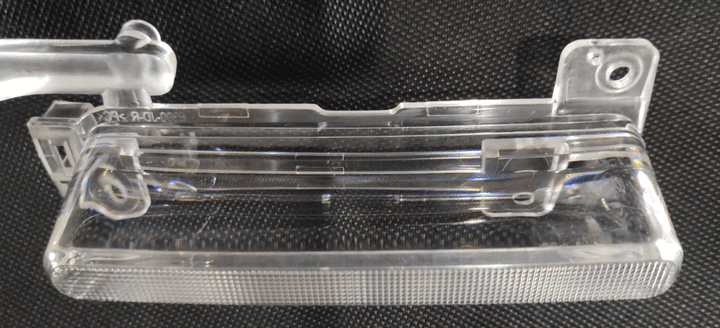

The Role of Cooling Systems

After injection, cooling channels rapidly extract heat so parts solidify fully before ejection. This influences factors like:

- Cycle time – Faster cool enables more cycles per hour.

- Part quality – Controlled cool minimizes warpage and residual stresses.

- Dimensional consistency – Even cool maintains uniform shrinkage in each shot.

- Process windows – Efficient cool broadens viable molding parameters.

- Tooling longevity – Effective heat removal protects molds from damage.

- Production costs – Optimized cool saves significant time and maintenance expenses.

Insufficient cool causes long cycles, defects, tool wear, and instabilities. Optimizing this system is essential for cost-effective molding.

Cooling Design Considerations

Key factors guide effective cooling system designs:

- Part geometry – Cool channels must match complex shapes.

- Material type – Coo is ready for polymer thermal properties.

- Cycle time targets – Cool balances rates and consistency.

- Cavitation – Multi-cavity molds require balanced cooling.

- Process settings – Cool accommodates maximum injection pressures and temperatures.

- Steel selection – Cool prevents localized heat damage of tool steel.

- Machinability – Drilled channels balance complexity with fabrication ease.

- Costs – Cool adds substantially to machining programming and process time.

With so many variables, optimizing cooling is challenging. This makes simulation tools invaluable.

Leveraging Digital Cooling Simulation

Advanced mold cooling analysis software enables optimization by virtually modeling heat transfer, flow rates, temperatures over time, and other factors.

Benefits of digital cooling analysis include:

- Visualization of thermal gradients

- Prediction of hotspots and bottlenecks

- Sizing for consistent cool times across cavities

- Iterating layouts and channel sizes

- Assessing drillability of proposed designs

- Validating against cycle objectives

- Quantifying improvement opportunities

- Communicating recommendations

By virtually simulating options, engineers refine designs before machining begins. This prevents costly rework.

Analysis capabilities simulate:

Conformal channels – Software automatically generates curved channels matching complex geometries.

Variable layouts – Alternative designs get modeled to compare performance.

Circuit sizing – Diameters and flows get optimized for each branch.

Cycle analysis – Transient models predict temperature changes over time.

Alternative fluids – Water, oil, and gas media get evaluated.

Additive channels – Inserts with complex printed cooling geometries get assessed.

Sensor placement – Virtual models determine optimal sensor locations.

Secondary cooling – Post-mold options like fans, fins, and heat pipes are modeled.

Manufacturing Collaboration

While simulation enables extensive design refinement, collaborating with an experienced mold maker provides additional benefits:

Machining expertise – Input ensures proposed designs are manufacturable.

Tooling materials – Performance gets matched with optimal tool steel grades based on cooling needs.

Fabrication methods – Casting, conformal additive manufacturing, and other alternatives add capabilities.

Sensor integration – Machinists determine best sensor mounting, wiring access, and protection.

Control schemes – Sequencing, timers, and temperature cutoffs get tuned for reliability.

Upgrade planning – Future modifications get considered in initial construction.

Cost tradeoffs – Enhanced cooling gets weighed against increased tooling time and expenses.

This manufacturing feedback helps balance an ideal optimized design with fabrication practicality and costs.

China’s Specialized Capabilities

Chinese injection mold manufacturers have deep expertise in cool system design, simulation, fabrication, and optimization.

Facing rising domestic labor costs over the past decade, Chinese companies focused intently on methods to reduce cycle times. Optimizing cool became an essential area.

Major investments went into advanced cool analysis software and training. Enhanced machining capabilities enabled fabrication of complex conformal channels. These strengths now provide global customers value through:

Faster cycles – Optimized cool cuts seconds off each cycle to improve productivity.

Higher throughput – Fast cool enables molding on smaller presses for lower capital costs.

Reduced defects – Consistent, balanced cooling minimizes part distortions and flaws.

Improved quality – Dimensional consistency and material properties see enhancement from controlled cooling.

Lower costs – Faster cycles, higher cavitation, and mold protection reduce manufacturing expenses.

Expert mold makers – Top Chinese mold makers provide cooling design services and quality fabrication.

Broad capabilities – Extensive experience with a wide range of tooling materials, channel geometries, and sensor integration.

By leveraging these cool optimization strengths, global manufacturers can reap significant time, quality and cost advantages.

Optimization Over Tool Life

The benefits of cooling analysis and design optimization continue over a tool’s operating lifetime through incremental enhancements.

Virtual models help diagnose production issues related to uneven cooling, localized hotspots, or changes in process parameters. Retrofit upgrades can then refine the system.

Common optimization steps include:

- Installing additional cool lines or adjusting sizes based on collected data.

- Adding protective coatings in high-wear areas.

- Implementing advanced controls for dynamic cool adjustments.

- Upgrading to conformal channels on existing tools using additive processes.

- Incorporating new sensor mounts and wiring access features.

- Moving or adding cool for new mold components like hot runners.

- Tuning control sequencing and temperature settings for optimal cycles.

Periodic cooling assessments ensure systems keep pace with evolving requirements over years of production.

Driving Innovation

Cooling optimization capabilities allow engineers to pursue innovative part geometries and advanced molding processes.

Conformal conformal cooling opens new design possibilities. Emerging methods like embedded printed circuits take optimization further. New polymers and applications place additional demands on thermal management.

By leveraging cooling analysis early in development, manufacturers can confidently develop the next generation of intricate injection molded parts that would otherwise pose unattainable production risks.

Cooling system optimization will only grow in importance as molded components increase in complexity. Advanced analysis combined with manufacturing collaboration enables innovation that drives the industry forward.