Imagine your ideal overseas supplier: a reliable partner who delivers your goods on time, every time. But the path to finding this gem isn’t always smooth sailing. Navigating price negotiations, building trust, and ensuring smooth procurement can be a maze. Fear not! We’ve charted the course, equipping you with 3 powerful tools: data as your compass, specialized software as your map, and a robust supplier qualification process as your guide. With these tools, you’ll overcome any obstacle and reach your sourcing destination – timely deliveries and a thriving partnership.

Focus on Solutions, Overcome the Problems

Cheap Today, Costly Tomorrow: Why Cutting Quality Isn’t Worth It

Your customers deserve the best, so why settle for less from your suppliers? While cheaper materials might seem like a cost-saving win, it’s a trap. Compromised quality translates to subpar products and unhappy customers. Refunds, replacements, and even lawsuits loom, erasing any initial savings. Remember, true value lies in long-term customer satisfaction, not short-term price tags.

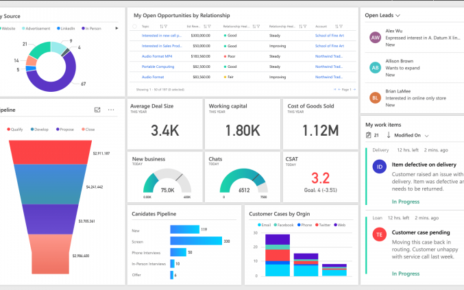

Solution: Break free from the price-only trap! Embrace a smarter strategy by building a KPI dashboard that monitors quality and cost simultaneously. Gain data-driven insights to make informed decisions about suppliers who offer true value, not just cheap prices. Invest in quality now, maximize long-term savings, and build a reputation for excellence.

Speak clearly, get it right

Vague specifications lead to delays and disappointment. Provide your supplier with crystal-clear details: grade, varieties, certifications, and usage. This ensures they deliver products that meet your exact expectations and delight your customers.

Solution: Say goodbye to guesswork, say hello to quality: Collaborate with your procurement team to create in-depth product descriptions and precise specifications. This collaborative effort ensures suppliers understand your needs, leading to faster development, higher quality products, and a competitive edge for your business.

Don’t Be Blinded by Sweet Talk: Conduct a Thorough Supplier Pre-Assessment

Imagine this: a supplier promises the world – the perfect product, the lowest price, lightning-fast delivery. It sounds too good to be true, right? Because often, it is.

Many businesses fall victim to smooth-talking suppliers, only to end up with disappointment and wasted resources. Why? Because they skip a crucial step: the supplier pre-assessment.

A pre-assessment is like taking your supplier out for a test drive before you commit. It’s a chance to assess their capabilities, reliability, and overall fit for your needs.

Solution: So, what should you do instead? Conduct a thorough supplier pre-assessment. Ask the right questions, Seek the right details, Verify everything.

By taking the time to conduct a proper pre-assessment, you can avoid costly mistakes and ensure you choose a supplier who will be a true partner in your success.

Speak Their Language: Aligning Supplier Goals with Your KPIs

Imagine this: you send a supplier your wish list, but they deliver something entirely different. Why? You never spoke the same language – the language of Key Performance Indicators (KPIs).

KPIs are the lifeblood of your business, measuring success and guiding direction. Yet, many fail to translate these crucial metrics to their suppliers.

Solution: Make KPIs a cornerstone of your supplier selection and management process. Prioritize metrics and KPIs. Define Clearly each KPI. Regular Communication and Conduct quarterly reviews to assess supplier performance against KPIs.

Ditch the Gut Feeling, Embrace Data-Driven Supplier Decisions

In the fast-paced world of business, making quick decisions is often crucial. But when it comes to choosing suppliers, relying solely on intuition or “gut feeling” can be a recipe for disaster.

Solution: So, how do you make informed, strategic decisions about your suppliers? Enter the power of data!

- KPIs: The Objective Scorecard: Key Performance Indicators (KPIs) provide unbiased, quantifiable metrics to evaluate supplier performance. Track on-time delivery rates, defect percentages, and other relevant metrics to identify reliable partners.

- Supplier Qualification Tools: Leverage technology to streamline the selection process. These tools gather and analyze supplier data, helping you compare options and identify potential red flags.

By embracing a data-driven approach, you can minimize risks, optimize your supply chain, and make supplier choices that contribute to your organization’s success.

Play it Safe: Secure Your Supply Chain with Written Contracts

Imagine this: you secure a great deal with a supplier, only for things to fall apart later. Disputes arise, blame gets thrown, and nobody’s sure who’s right. Why? You didn’t have a written contract.

Solution: Don’t leave your business exposed! Before shaking hands, ensure a lawyer experienced in international trade helps you draft a watertight contract. This investment upfront can save you countless headaches and financial losses down the line. The most important thing keeps your documents safe in a Document Management system.

Maverick Shopping: Taming the Procurement Bypass Beast

Imagine this: you meticulously build a procurement system, only to discover rogue purchases popping up like weeds. That’s the reality of procurement bypass, where employees or departments circumvent established processes and buy things on their own.

Solution: Streamline Procurement with open communication, simple process and workflow, and transparency. Utilize procurement software to automate approvals, track spending, and enforce compliance, reducing opportunities for maverick behavior.

Don’t Get Blinded by Inflation: Proactive Strategies for Smart Sourcing

Inflation might seem like a distant rumble, but for savvy procurement professionals, it’s a constant drumbeat demanding attention. Predicting its exact impact is a challenge but ignoring it entirely can leave your business scrambling later.

Solution: Regularly monitor inflation indices and analyze how they affect your specific supply chain costs. Build inflation projections into your negotiation strategy, seeking flexible contracts with adjustment clauses or alternative pricing models.

Consider diversifying your supplier base or exploring alternative materials to mitigate risk and leverage competitive pricing. Invest in technology: Utilize data analytics tools to track cost fluctuations and identify proactive cost-saving measures.

Unlocking Success: Mastering the Art of Supplier Management

Navigating the world of suppliers can be like traversing a bustling marketplace – exciting, yet potentially overwhelming. While challenges inevitably arise, conquering them isn’t just possible, it’s the key to thriving partnerships and a resilient supply chain.

Remember, the solution lies not in brute force, but in partnership and proactive collaboration. Foster an environment of clear communication, transparency, and shared goals. By doing so, you’ll:

- Proactively identify and address potential risks, transforming them into opportunities for improvement.

- Strengthen supplier relationships through a robust supplier qualification process that ensures compatibility and efficiency.

- Boost your bottom line with regular performance evaluations, timely feedback, and constructive negotiations.

Think of supplier management as an investment, not just a necessity. By following the supplier qualification process you will cultivate mutually beneficial relationships, and you’ll unlock a wealth of benefits: enhanced efficiency, improved profitability, and a robust supply chain that empowers your business to reach new heights.

Remember, the journey to successful supplier management begins with a single step: choose collaboration over competition and watch your partnerships flourish.